The four steps of success

CuraTio

With the support of development partners, Gloss & Coating has developed a optimally tuned technology for the Electronics & Automotive industry to change tool surfaces in the sub-micron range.

The technology is based on four blocks that are revolutionizing the "surface DNA".

Thus, Gloss & Coating can change process-relevant properties such as the tendency to form deposits and demolding forces, which influence the appearance and feel of the parts and the cycle times, among other things. We have already applied this technology to a large number of problems in injection molding and have successfully used it with numerous customers in a wide variety of industries.

Due to the manipulations in the nano range, it is also possible to rework tools that are already in production with the CuraTio process.

Gloss & Coating is thus able to remedy the current cost drivers in production.

- Minimization of demolding forces

- Cycle time reduction

- Extension of maintenance intervals

- Extension of the process latitude

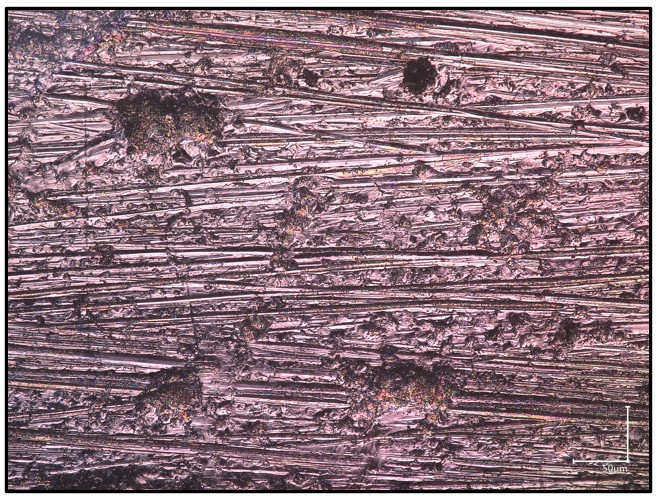

Automated Polishing

CuraTio - AP

The first CuraTio block is a surface treatment process to reduce the initial roughness and remove the white surface layer.

- Can be used for all common materials

- Safe, Precise and Reproducible

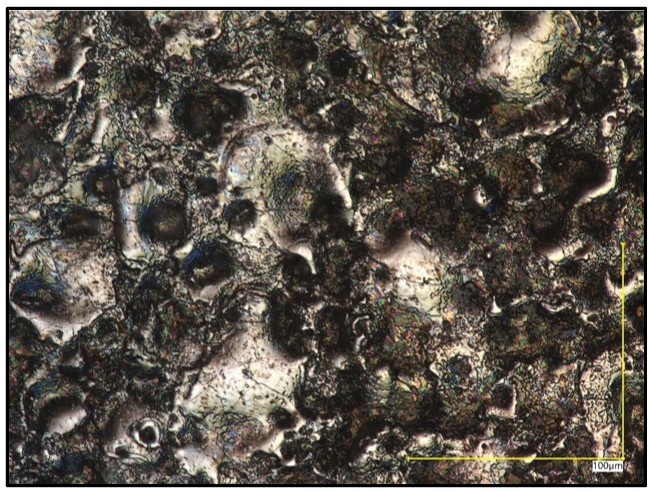

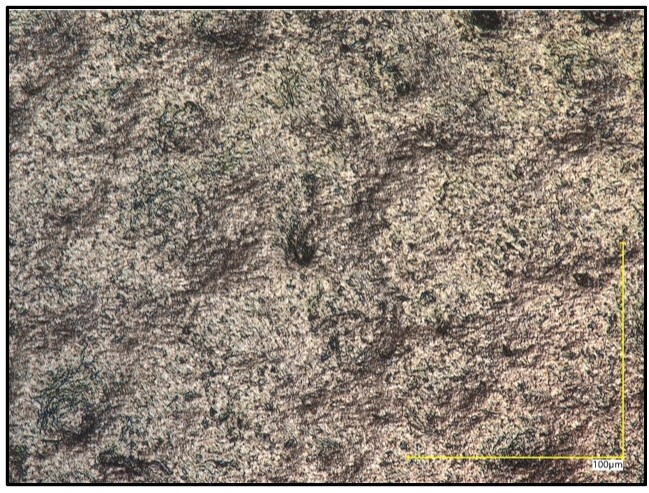

Nanostructuring

CuraTio - ST

In the second process step, the steel/plastic contact surface is given a nanostructure. This is the pre-treatment for setting the surface polarity.

- Uniform demolding properties

- No geometric restrictions on the components

Demolding

CuraTio - DM

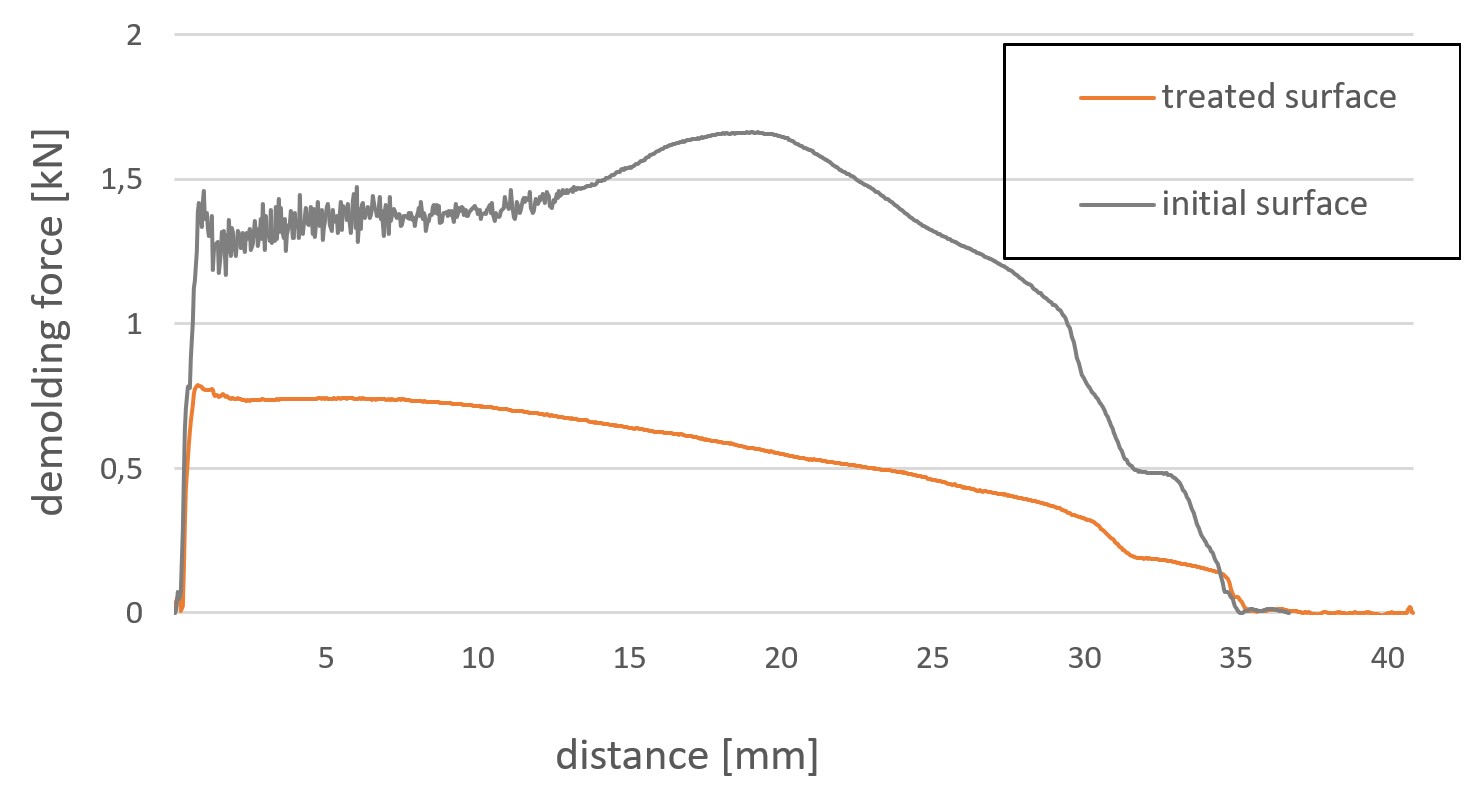

The third CuraTio block sets the surface polarity for the specific application. This results in active support for demolding and deposit formation properties.

- Demolding forces reduced by up to 60%

- Deposit formation properties improved by up to 90%

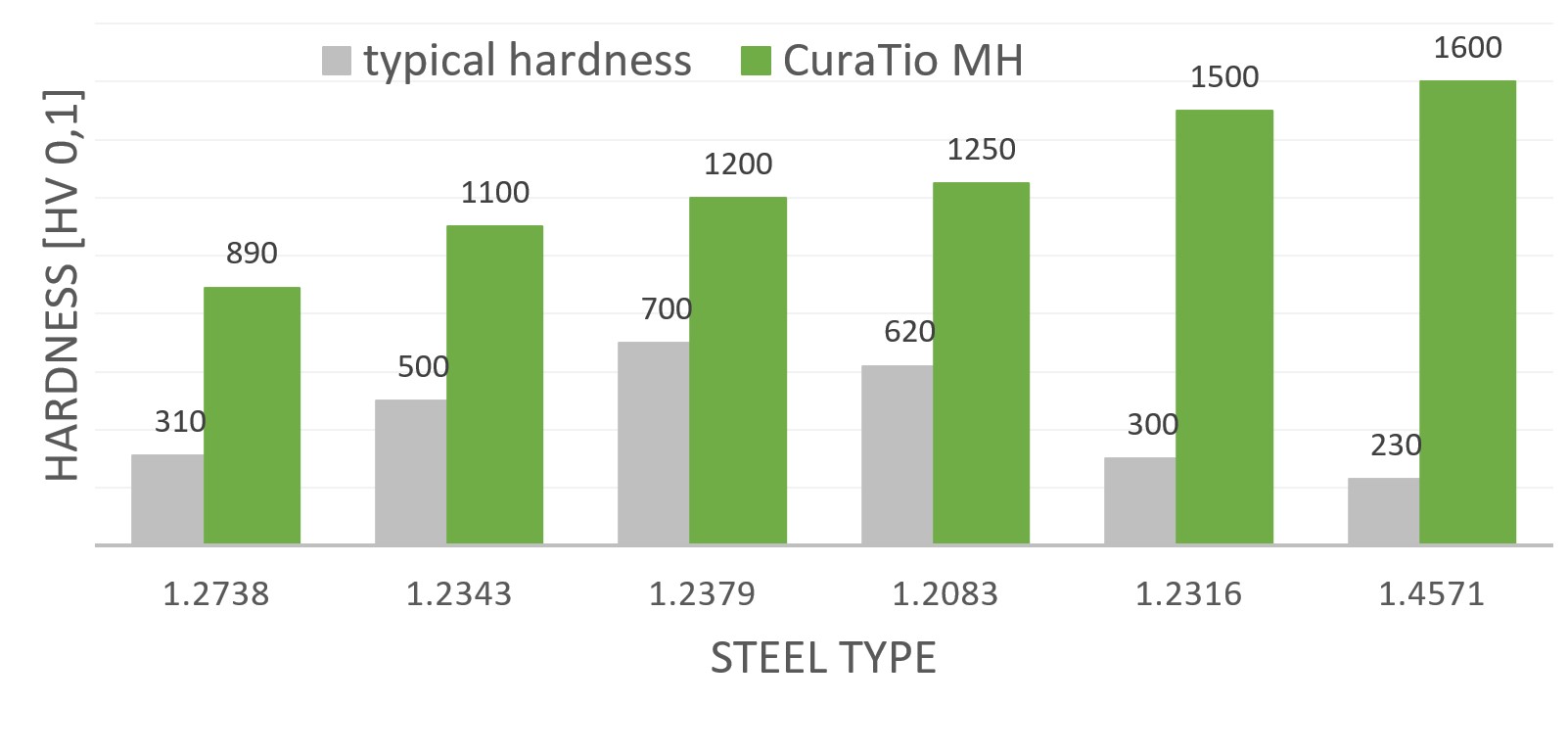

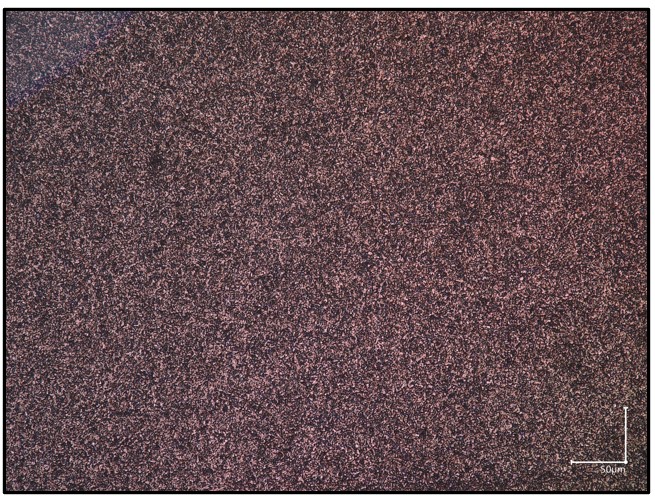

Microhardening

CuraTio - MH

Finally, the previous CuraTio blocks are sealed with cold diffusion that is tailored to the material and geometry.

- High surface hardness

- Protection zone 30-50µm

- Sealing in 0-geometry

- Repairable