INNOVATION

Demolding Optimization

We have developed the process “Nanostructuring” which allows us to selectively control the tertiary structure which heavily influences the interaction between the plastic material and the tool surface, i.e., sticking, residue formation, and friction.

It is important to know that by changing the tertiary structure with the help of Nanostructuring only the physical nature of the surface is changed, not its chemistry. Therefore, Nanostructuring is NO coating making it ideally suited for the medical industry which is typically very reluctant to use coatings to produce injection molded parts.

While Nanostructuring has the potential to eliminate the need for coatings as an alternative for solving demolding/sticking/residue problems, it cannot act as a barrier to corrosive attack on tool surfaces and tool parting areas. Also, for the demolding of very challenging material such as TPU, TPE, etc., the Nanostructuring method might not be enough.

There have been increasing problems with corrosion formation in contours and tool parting areas due to highly aggressive flame-protection used for all plastic parts related to the growing field of electromobility as well as more aggressive plastic materials used in medical injection such as COC, COP.

There are coatings which have the potential to solve the corrosion problem (which in most cases is related to residue formation) but all have their drawbacks. While Nickel is an excellent barrier coating against corrosion it only works satisfactory above coating thicknesses of 2/100mm - way too high for low-tolerance tools; the same holds true for PTFE-type coatings. PVD- und Chromium-type coatings are only corrosion inhibitors but have no real corrosion-protection properties. Defect-free PACVD coating such as DLC also have corrosion-protection properties, but they depict unfavorable interactions with almost all types of plastic materials. All coatings have thicknesses between 2-3 µm.

As an answer to this dilemma, our team has developed a coating called “Duomorph” with superb corrosion protection properties and a coating thickness of only 0,1 µm (!). The coating material has an FDA- and a USP Class VI (Cleanroom) certification making it ideally suited for the medical industry.

Example

Application with Nanostructuring

The following example shows the potential of nanostructuring to reduce demolding forces associated with the injection molding process without applying a coating:

Three cores were polished to an initial SPI-A1 finish (industry standard). One core was then treated with a fine, one with a coarse nanostructure, while one core remained in the initial high-gloss quality. The cores were then imstalled in an injection molding tool and article of transparent polycarbonate were manufactured. The transparency of these articles was not negatively affected by the nanostructuring.

The demolding forces and the demolding path were measured during the process with the help of sensors:

Example

Application with Nanocoating

For a medical application, a customer is producing very thin mats made from TPE – an extremely difficult demolding situation.

Due to the very strong adhesion of the TPE to the surface no production was possible – the mat was torn by the ejector pins.

Several coatings were tested – without success.

After applying a combination of Nanostructuring and Nanocoating to the EDM-structured surface the customer was able to produce without any problem.

Example

Application with Nanostructuring and Nanocoating

The following example shows the potential of nanostructuring in conjunction with the "Duomorph" nanocoating to reduce demolding forces.

One cavity was left in its entry surface and a second cavity was treated with fine nanostructuring and the "Duomorph" nanocoating. The cavities were then installed in an injection molding tool and articles made of thermoplastic elastomer were produced.

The demolding forces and the demolding path were measured during the process with the help of sensors:

Advantages

Nanostructuring

- No Change of the Secondary Structure and Insert Geometry

- Substantial Reduction of Demolding Forces, Uniform Demolding Properties of ALL Cores/Cavities

- Little or no Influence on the Appearance of the Part Surface

- Elimination of the Machine or Manual Effect on the Tertiary Structure, i.e., all parts look the same – a very Important Aspect for Multi-Cavity Tools

- Can be Readily Combined with Micro GL and Nanocoating

Advantages

Nanocoating

- Coating Thickness Approx. 0,1µm

- Surface Energy < 18 mN/m

- Corrosion Protection for Tool Parting Areas and Contour Surfaces

- ACTIVE Support of Surface Demolding Properties

- Can be Combined with Nanostructuring

- No Geometric Restriction for the Substrates to be Coated

- Very Good Substrate Adhesion, Coated Surface can be Subjected to US Cleaning

- Coating Material is FDA- and USP Class VI- Certified

- Successfully Tested in more than 100 Demanding Customer Application Settings

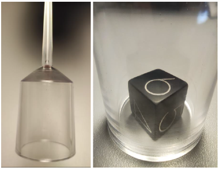

Example

Deburring of inserts for medical injection molding

Deburring of holes in a metal transformation part

Deburring the inner bores of a copper part

INNOVATION

Automated Deburring

After the last machining step, deburring of the manufactured part is necessary in most cases. There are a variety of methods and machines available that can fulfill that task satisfactorily in most cases. Sometimes however, the geometry and/or sensitivity of the parts make it difficult or impossible to debur employing the conventional methods.

Based on our MicroGL process we have developed a highly effective deburring method which depicts almost no geometrical restrictions and can also be used on sensitive parts and/or materials such as Copper, Aluminum, etc.

This deburring process is very fast and tailored to the parts geometry. Additional advantages are a uniform, smooth surface appearance and no need to introduce separate cleaning procedures after deburring. We are in the process of automating certain aspects of it thus enabling the deburring of large numbers of parts.

We are already employing this method for injection molding inserts but companies manufacturing large numbers of sensitive metal transformation parts as well as milled parts also have expressed a profound interest in this new technique.

Advantages

- Fast

- Safe, Precise and Reproducible

- Preservation of Edge Sharpness for Injection Molding

-

Usable for a Variety of Materials

(e.g., Metals, Plastics, Ceramics)