Process Development

On request, we develop, in close cooperation with development partners and research institutes, tailor-made processes in the areas of automated polishing and deburring as well as surface modifications for your application-specific needs.

Technology Overview

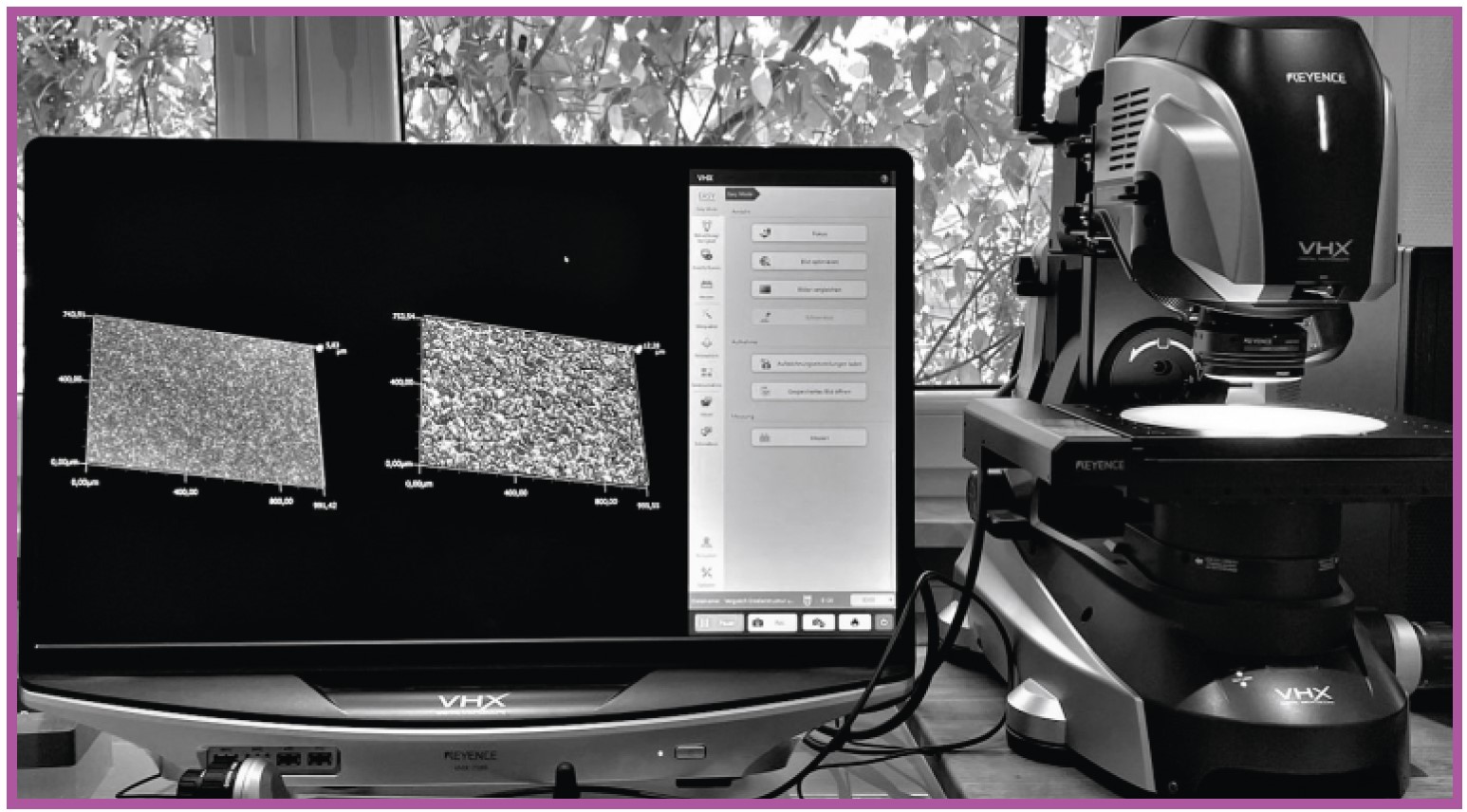

- Digital Microscope - Keyence VHX 7000

- Confocal Laser Scanning Microscope - Keyence VK-X 3100

- Optical 3D Measurements - Keyence VL 570

- Optical Microscope - Zeiss Stemi DV 4

- Optical Contact Angle Goniometer - dataphysics OCA 25

- FTIR spectrometer - Thermo Fischer Scientific Nicolet Summit X

- Roughness Measurements - MarSurf PS 10

- Tactile Measurements - Micro-Hite 600

- UCI hardness tester - Sauter HO 1K

INNOVATION

How we Validate our Developments

Internal quality assurance is our most important asset. To validate our process developments, we rely on modern digital microscopy, streak light projection and roughness measuring devices.

We also use the existing technologies for analyzes and measurements for our customers.

Cooperation with the Plastic Institute Lüdenscheid

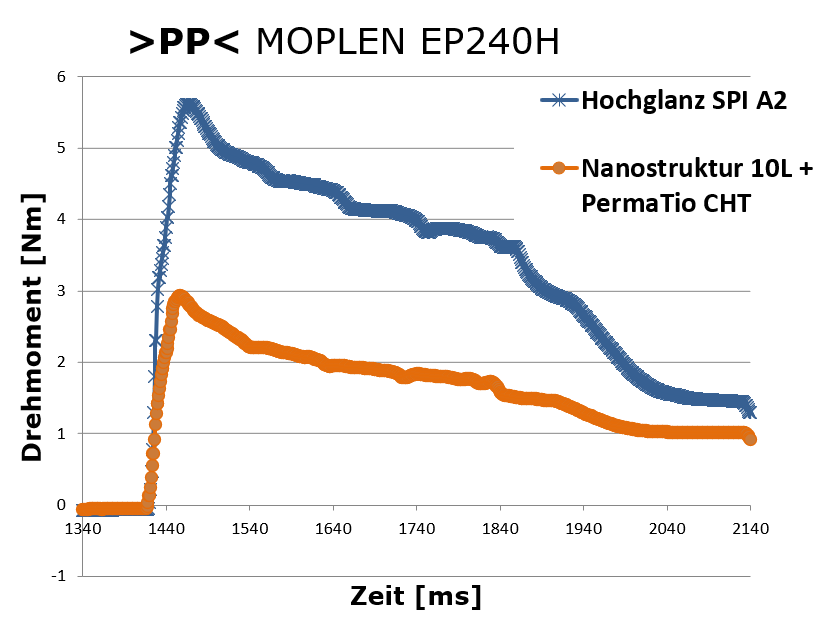

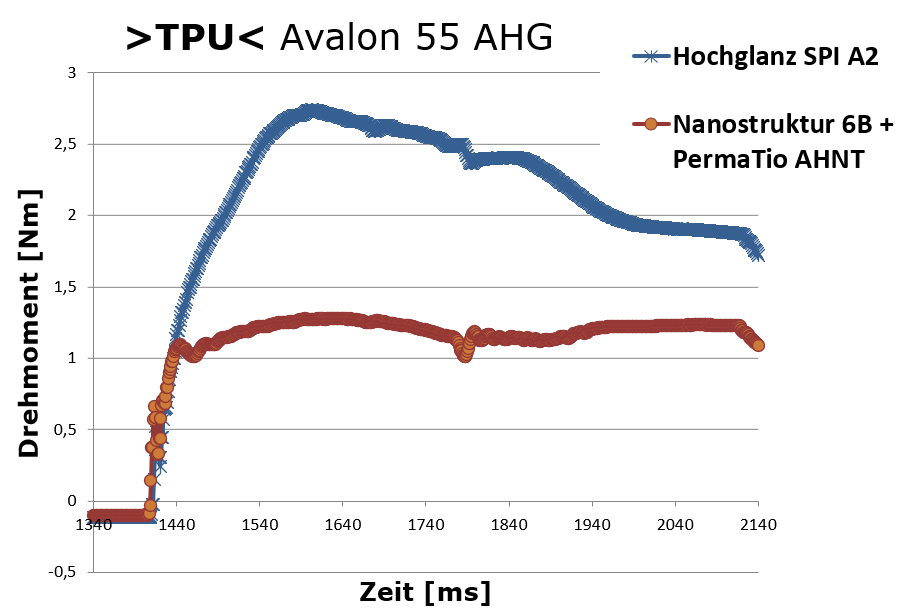

The experimental tool of the Plastic Institute Lüdenscheid for capturing the demolding forces represents a measuring instrument with which the demolding-relevant surface effects between the tool surface and plastic melt can be evaluated. By means of a torsional movement of the mold insert, which can be exchanged through a quick-change system, the torque necessary for detachment (or "demolding") is recorded over time. In this process, the insert rotates by 180 degrees. During the rotational movement, a surface pressure between the mold insert and the molded part can also be set and monitored by means of measurement, so that swelling effects and their influence on the surface phenomena can be traced.